Modern cars began to be equipped not only with improved gearboxes, but also with a double clutch. This id is one of the best today, we will tell you about the principle of operation and its structure.

The content of the article:

- Variety in cars

- Wet

- Dry mechanism

- Graphic Description

Many robotic gearboxes today have dual clutches. In addition to the standard clutch assignment, it preselects the next gear when the previous gear is engaged. This choice is achieved due to the alternating operation of the friction clutches.

Thanks to this well-adjusted operation, the torque is continuously transmitted to the drive wheels from the engine.

A variety of mechanisms

The double clutch, as already understood, works in concert with the gearbox. In robotic gearboxes with a dual clutch, a different clutch is used for odd and even gears. We can say that in fact they are two different boxes that are in the same case and work as one.

For the first time, the use of a double clutch was mentioned in 1980 by Audi and Porsche, who used their developments for their own sports cars. Nowadays, it migrated to production models and received the name:

- Speedshift at Mercedes-Benz;

- Twin Clutch SST for Mitsubishi;

- S-Tronic for Audi;

- 7DT - Porsche;

- Powershift - Ford;

- BMW - M DCT;

- DSG - Volkswagen.

This is not yet a complete list of manufacturers who use this technology for their vehicles.

Despite the name of the automaker's company, the manufacturer of the "dual" is very different. Due to the complexity of the technology of operation of such a mechanism, manufacturers are distinguished:

- ZF for Porsche cars;

- Luk - for Volkswagen as a dry clutch;

- BorgWarner - for Volkswagen as a wet clutch;

- Ricardo - the most famous for the Bugatti Veyron;

- Getrag - for cars of Chrysler, Volvo, Mercedes-Benz, Ferrari, Ford.

It often happens that car manufacturers combine parts and separate systems from different manufacturers. For example, BMW from BorgWarner takes a dual clutch, and from Getrag the gearbox.

"Wet" double

There are two types of clutch, dry and wet (it is also multi-disc in oil). The so-called "wet" has better cooling. Most often it is installed on gearboxes with a torque of 250 Nm and more. An example would be the Bugatti Veyron, which reaches 1250 Nm of torque.

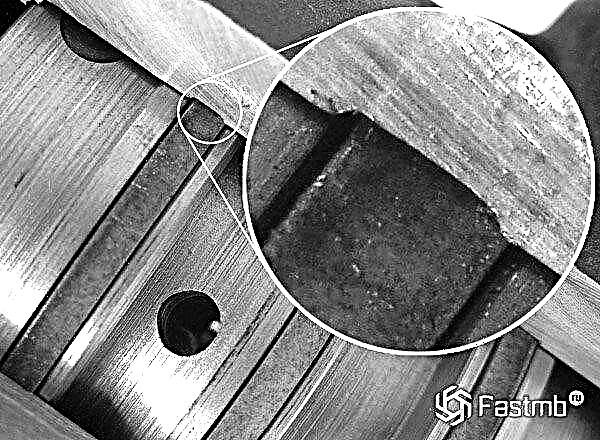

At the heart of the wet dual clutch are two sets of friction discs that are housed in a single housing. In each package, some of the discs are rigidly fixed to the clutch housing. In turn, the clutch housing is connected to the car's engine through hubs.

The second set of discs is mounted on separate hubs, which are located on the input shaft of the respective gear row. In the normal position, the mechanism will be open. As for the closure, this is done thanks to the hydraulic cylinders under the control of the electrohydraulic module. The discs take the initial position due to the springs.

Depending on the design of the dual clutch, the disc packs can be arranged in different ways, concentrically or parallel. Concentric when the couplings are in the same plane and perpendicular to the input shaft. In this position, the couplings are more compact. Typically used in front-wheel drive gearboxes with a transverse engine arrangement, the inner clutch is usually responsible for shifting even gears, and the outer clutch for odd gears. It becomes clear that such a set is designed to transmit a lot of torque.

Parallel - when the couplings are located one after the other. Typically, this arrangement is used for rear wheel drive vehicles.

Dry double

As mentioned above, the wet clutch is set for torque from 250 Nm. As for the dry clutch, the maximum torque for it is 250 Nm. The efficiency of this clutch is achieved due to the smallest power loss of the unit to drive the oil pump.

This type of clutch includes a drive disc that is connected to a dual-mass flywheel. Two dry clutch discs, which are located on the input shafts of the gearbox, two pressure discs. It also includes two diaphragm springs, two release bearings and, as is clear, two levers for engaging the clutch.

In the normal position, the mechanism is open. The whole principle of "dry" operation is based on the transmission of torque to the required clutch disc from the drive disc, and then to the corresponding input shaft of the gearbox. As a rule, each dry clutch works independently of each other, which gives greater reliability.

When the clutch closes, the lever presses the release bearing against the diaphragm spring, which in turn transfers all the force to the pressure plate, and then to the clutch disc. The clutch disc itself is pressed against the drive disc, after which the torque is supplied to the primary shaft of the gearbox.

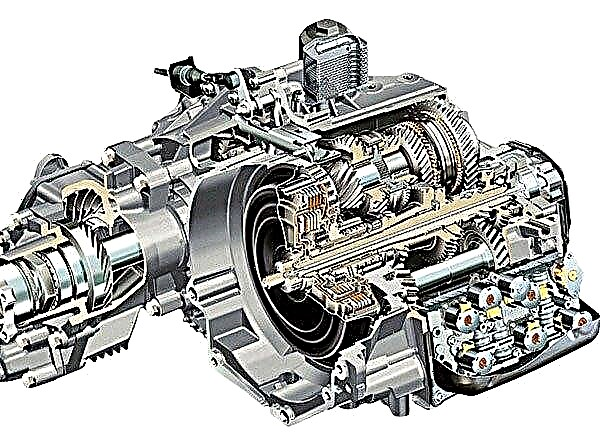

Graphical diagrams of wet and dry clutches

Wet dual clutch diagram:

- Input hub;

- Coupling hub first;

- Second clutch hub;

- Leading disc;

- Clutch disc pack second;

- Clutch disc pack first;

- Diaphragm spring;

- Piston;

- First clutch hydraulic cylinder;

- Input shaft for 1 row;

- Input shaft for 2 rows;

- The main hub;

- Piston;

- Coil spring;

- Secondary clutch hydraulic cylinder.

Dry double clutch diagram:

- input shaft 1;

- release bearing 2;

- diaphragm spring 2;

- first pressure disk;

- master disk;

- dual-mass flywheel;

- clutch disc 2;

- pressure disk 2;

- clutch disc 1;

- diaphragm spring 1;

- release bearing 1;

- input shaft 2.